Control and safety of the quality of flour and fish oil

2022-05-27 11:21

Freshness of raw materials: The freshness of raw materials is closely related to the protein quality of the finished product. It is very important to shorten the time interval between fresh fish harvesting and processing, and use ice water to keep fresh fish fresh to prevent spoilage. The deterioration of fresh fish produces biogenic amines, such as histamine and cadaverine, which can be used as indicators to judge the freshness of fishmeal.

Freshness of raw materials: the freshness of raw materials is closely linked to the protein quality of the finished product. It is essential to shorten the time interval between harvesting and transformation of fresh fish and using ice water to keep the fish fresh in order to avoid its deterioration. Fresh fish deterioration produces biogenic amines like histamine and cadaverine, which serve as indicators to assess the product's quality.

Temperature control during treatment: control of the treatment temperature in a factory plays an important role in the production of high-quality fish flour. Controlling the cooking and drying temperatures below 90 °C can improve the nutritional value of the finished product, particularly its digestibility, while also inactivating the harmful bacteria in the raw materials.

Fat stability: Fish flour and fish oil have a high content of polyunsaturated fatty acids such as EPA and DHA, which are easy to oxidize and degrade; therefore, it is advised to add dd antioxidants like ethoxycin to them, particularly in hot environments.

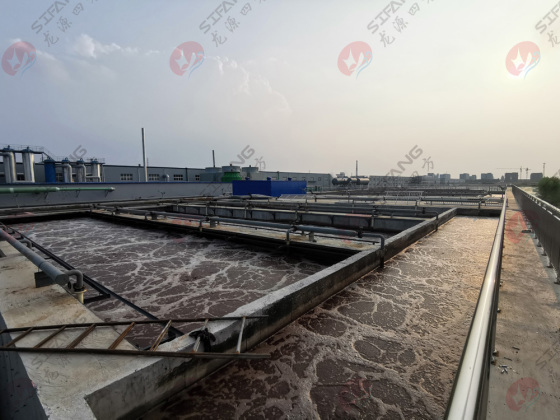

Sanitation control: To enhance the quality of finished products, it is crucial to keep fresh fish storage devices and equipment, transport equipment, factory fish storage tanks, and other devices and equipment clean and hygienic to prevent spoilage. Production factories must segregate the dry and humid parts and minimize the movement of people and equipment between the various production areas. Production plants must take strict measures to prevent contamination of products finished by Salmonella, Vibrio cholerae, and Shigella bacteria. Furthermore, we must safeguard production factories from the infiltration of insect, animal, or bird excrement. The factories must then establish a practical health control system.

Humans are the primary consumers of most farm animals. As a result, a safe and hygienic animal diet has a significant impact on the health of both animals and humans. Therefore, all food quality control organizations, such as IFSA, FEMAS, ODOCOM, PDV, QS, and others, pay close attention to the safety and hygiene of these foods and the production chain. The International Feed Safety Alliance (IFSA) is a joint effort between the main European associations for controlling the animal feed industry, including the British and agricultural federation, based on Feed Material Assurance Mechanism (FEMAS), and the Belgian OVOCOM, based on best animal feed (GMP) food manufacturing practices as a standard. The Dutch Committee on Animal Food Products (PDV), based on the quality and safety insurance system for the animal food production industry (GCM+), the German organization QS, based on the animal feed quality standard Manual (QS), and the European Federation of the Animal Food Industry (FFAC) all contribute to the International Feed Safety Alliance (IFSA). The system is based on the ISO 19011:2002 standard and the HACCP (HAZARD Critical Control Point) mechanism, which covers specific requirements for inspectors and inspectees. The Hazard Critical Control Points (HACCP) mechanism requires external inspectors to identify critical control points, monitor them strictly, and record the relevant information. When there is a gap outside the authorized margin, the external inspection staff must immediately investigate and, at the same time, record the problems and solutions in detail in the survey. A quality insurance system guarantees that the products are safe, pure, and traceable.

Traceability: Flour and fish oil users should be able to retrace the entire process of manufacturing flour and fish oil, from production to transport and storage.

Sanitary security: purity and other indicators of flour and fish oil meet quality standards stipulated by law and do not contain pathogenic organisms, mycotoxins, or natural toxins.

No pollution: Flour production factories and fish oil should only work with fish, crustaceans, or maritime molluscs, not mammals, birds, or other animal species. Production factories must set up an effective detection mechanism to prevent flour and fish oil contamination during production and processing.

Previous:

Other

The Longyuan Sifang fish flour machine is exported to the four corners of the World.

2022-05-27

Dinghai News Network News On November 5th, in the production workshop of Zhejiang Longyuan Sifang Machinery Equipment Manufacturing Co., Ltd., workers were nervously installing fishmeal production equipment. According to reports, the steam-type wet fishmeal dryer produced by the company was awarded the title of “Made in Zhejiang” last year, and its products are exported to more than 50 countries such as the United States, Poland and Brazil.

This standard of "Made in Zhejiang" is determined by Longyuan Quartet!

2022-05-27

Zhejiang Longyuan Sifang Machinery Equipment Manufacturing Co., Ltd. formulated the "Steam Type Wet Fish Meal Dryer" "Made in Zhejiang" group standard, which was approved and released by Zhejiang Brand Building Federation. This is the first "Made in Zhejiang" standard released by Dinghai District this year, marking that Dinghai District has taken another step towards the "Made in Zhejiang" certification.